Exclusive interview of Cotest test: "tailor" for VCSEL enterprises to greatly optimize customer customized test experience

According to Myers Consulting, Cotai Testing, which focuses on electronic instruments and testing technology, has mainly provided testing services for traditional optical communication enterprises since its establishment in 2012. When Apple released the iPhone X in 2017, Cotest Test keenly "smelled" the potential opportunities of the VCSEL industry. In recent years, we have worked closely with many VCSEL start-ups in China. Cotest Testing has actively explored, and has successfully developed customized VCSEL testing schemes with its profound technical accumulation and steady practical style!

Cotest Testing is headquartered in Wuhan. In the process of exploring VCSEL testing business, it has a similar experience with Wuhan - after suffering, it finally achieved brilliance. On September 24, 2020, Mr. Zhang Qian, General Manager of Cotest Testing, shared the rapid development and latest R&D achievements of the company in the past year at the "30th" Meaningful "Seminar: 3D Vision Technology and Application" hosted by Myers Consulting.

Mr. Zhang Qian, General Manager of Cotest Testing, introduced VCSEL test modules and main indicators

Great progress has been made in the past year, and a new image has appeared for the first time

At the beginning, Mr. Zhang Qian said frankly "We have been involved in the systematic testing of consumer VCSEL since 2017, and before that, we were mainly engaged in the testing of optical communication VCSEL. To be frank, at the beginning, we did not know how to test, but we crossed the river by feeling the stones. Now, in addition to mobile phone applications, more new applications of VCSEL have emerged. Every new application involves the testing of components before it is launched upstream."

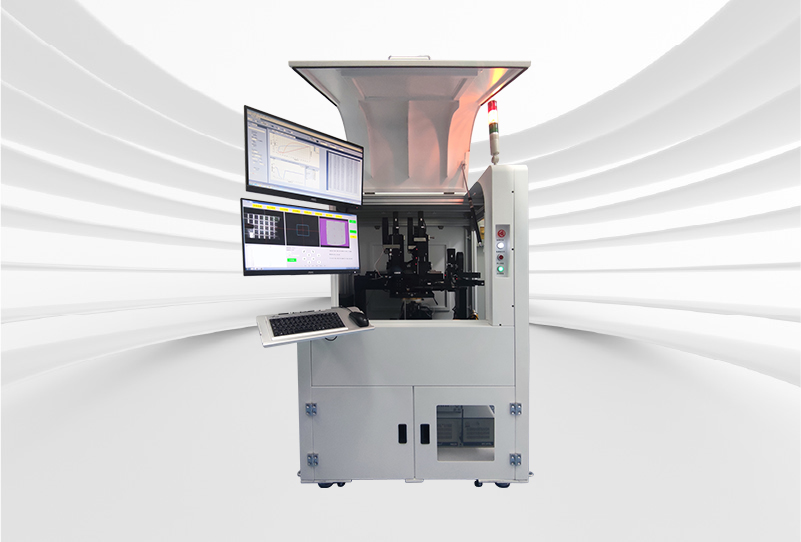

In the past year, Cotest Testing overcame many difficulties and continued to promote VCSEL testing services. This year, the newly built Cotest Optical Core (Changzhou) Central Laboratory in Changzhou was completed: it has built its own purification testing laboratory and is equipped with independently developed VCSEL manual and semi-automatic testing machines, which will be able to provide more professional testing conditions and verification services for 3D sensing VCSEL industrial chain customers. The new image of Cotest Test also appeared in the "Meaningful" seminar for the first time. The new logo aims to convey the following moral layers: the calm blue and the bright green represent the development philosophy of Test - steady and innovative; The flexible oscillogram curve combined with the circular pattern of the chip reflects the focus and expertise of Testing. Whether it is testing and measuring instruments and equipment, or customized testing solutions, Testing can provide professional and efficient one-stop services.

New LOGO tested by Cotest

Six VCSEL test modules greatly optimize the user customization experienceThrough experience accumulation in recent years, Cotest Testing summarized VCSEL testing into six modules. Each module provides different performance options. At the same time, according to the characteristics of the tested parts of customers, with targeted test equipment, test fixtures and methods, the customization experience of users can be greatly optimized: simple and complete, abundant and frugal, manual and automatic, R&D and mass production.

Module 1: LIV module. LIV is a required test item of VCSEL. Unlike the CW mode used by the optical flux laser, the VCSEL test method usually uses the QCW (pulse) mode, and the pulse width is getting narrower and narrower, which leads to many new problems. For example, Mr. Zhang Qian mentioned that in the past, CW mode was used for testing, but now it is excited by microsecond pulse current. This brings a problem that is easy to ignore: how to find the correct voltage sampling point when measuring voltage? The overshoot, oscillation and other characteristics of pulse excitation will cause the change of voltage within the pulse. If the sampling point is not accurate, the optical power and PCE results will have a large deviation, causing users to misread their product indicators. This kind of "small problems" can be seen everywhere in VCSEL's testing system. Based on the experience accumulated in general testing, Kertai Testing can quickly solve these problems, allowing users to focus on their products rather than solving testing problems.

Module 2: Near field optical analysis. Near field optical analysis mainly uses high-resolution cameras to obtain images, and outputs energy intensity, center of mass position, ellipticity, total luminous points, bad/dark points, uniformity and other indicators through the algorithm. Among them, how to ensure the consistency of near-field test focus is a difficult point. Mr. Zhang Qian introduced that "we have adopted adaptive algorithms to solve this problem, using self-developed automatic focusing and spot analysis algorithms to judge, so as to reduce the error caused by manual focusing".

Module 3: Far field optical analysis and human eye safety. Far field optical analysis test items include FOV, energy distribution, window efficiency, contour, uniformity, etc. Cotest test uses two methods to achieve far-field FOV test: direct imaging of target surface (small angle) and secondary imaging of transmission film (large angle). test also supports multiple spot boundary algorithms (D50/D86) in software, and supports some large angle spot divergence angle tests (such as FOV=120 °). At the same time, test realizes the evaluation of far-field spot energy distribution and window efficiency through self-designed algorithms and analysis methods, In terms of human eye safety, Test also has two evaluation methods for human eye safety: 7mm aperture integrating sphere and software algorithm calibration. The whole test standard follows the eye safety test standard of IEC60825/GB7247, etc.

Six VCSEL test modules (first to third modules) tested by

Module 4: TR/TF test. At present, TOF applications, such as LiDAR, put forward high requirements for the time domain response of VCSEL chips. The narrower the pulse width, the higher the time resolution. At present, Testing has launched a TR/TF test scheme for narrow pulse width. The difficulty of this test project is how to overcome the parasitic parameters of the laser and how to coordinate the high current output and fast modulation frequency (nanosecond level). Mr. Zhang Qian shared the solution of test, and realized non-destructive TR/TF test through board and circuit optimization and fixture design.

Module 5: Temperature drift test. VCSEL chip wavelength and power are extremely sensitive to temperature changes. The above four tests involve temperature related tests. In addition to the high temperature environment, chip failure is likely to occur in some low temperature situations. At present, Testing has the ability of high and low temperature testing from low temperature - 20 ℃ to high temperature 100 ℃.

Module 6: System calibration. System calibration is often ignored, but when it comes to mass production testing, the differences of the test systems themselves will cause great differences and consistency in VCSEL test results. Testing ensures the accuracy and consistency of the testing system through the original factory calibration and the calibration of key system components (such as integrating sphere, lens and CCD image sensor).

Six VCSEL test modules (the fourth to sixth modules) tested by

Four products and services to meet the different needs of various VCSEL enterprises

Based on the six test modules of VCSEL summarized through exploration, Testing has the ability to provide the following four types of product services for VCSEL enterprises: (1) Finished machines: For customers who do not have the energy to do test research and development, Testing provides mature machines to provide mass production test services; (2) System integration: For customers with trade secret considerations, they can build their own test systems. Testing provides services in terms of test process design, test fixture preparation, test software and data connection, aiming to reduce the cost of trial and error for customers and shorten the time for building test processes; (3) Test hardware: Test knows the "personality" of different test instruments on the market, and can provide cost-effective hardware supply according to the specific needs of customers; (4) Agent testing service: This is a new business of Testing. It hopes to cooperate with customers and provide them with a complete VCSEL test report.

柯泰测试为VCSEL企业提供的产品和服务

tests the products and services provided to VCSEL enterprisesAt present, all VCSEL enterprises are actively laying out the next generation VCSEL technology. As their "rear area", Testing also keeps up with the development trend of VCSEL technology in the next few years to ensure that VCSEL's new products have strong test support services. Mr. Zhang Qian introduced to the audience in detail the plans of Testing for 3D sensing VCSEL testing services in the coming years, such as LIV testing for extremely narrow pulses, testing for high power VCSEL, multi junction VCSEL, matrix VCSEL, and testing scheme for VCSEL in flip chip form.

Testing 3D Sensing VCSEL Testing Service Planning in the Next Few Years

Finally, Mr. Zhang Qian said that Test has a complete test system for the whole industry chain and key components of VCSEL. VCSEL industry has not yet entered a truly explosive stage of development, and many manufacturers are trying to enter. In addition to smart phones, many non mobile applications have been extended in China. The responsibility and role of Testing is to help customers provide customized testing services when introducing new products. In the field of VCSEL testing, the mission of Testing is to save time for customers, improve efficiency, accelerate the speed of product introduction to the market, and really help the development of VCSEL industry!